Company

Hilty Engineering AG

Hilty Engineering AG specialises in the manufacture of complex injection moulded parts and assemblies. Hilty already supports customers in the development and design of new components. The moulds, which are designed in advance using filling simulation, are manufactured in the company's own mould shop. The modern machinery includes injection moulding machines with closing forces of 180 to 1100 kN.

Gallery

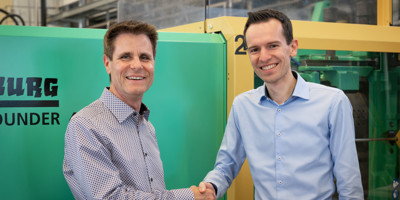

In summer 2024, KUNDERT took over Hilty Engineering AG, expanding its product portfolio to include plastic injection moulding and toolmaking. This enables the customers of both companies to be advised and served even more comprehensively. The merger creates the only Swiss company that can process high-performance plastics and polyurethanes by machining as well as injection moulding and hot moulding.

Development and design

Our highly experienced engineers and technicians will be happy to help you realise your project. We are happy to work closely with your design department and provide you with advice and assistance. In accordance with your specifications, we will help you select the raw materials and take care of the plastic-compatible design.

- Product design and feasibility studies

- Component development and material selection

- FMEA analyses, FEM calculations (strength analyses)

- Rheological calculations (Moldflow® filling simulation)

- Prototypes

Mould making

The mould is the decisive factor for a high-quality plastic part. Experience and in-depth knowledge of injection moulding and mould making are the prerequisites for the optimum design of the moulded part and mould. In-house toolmaking, modern production techniques and qualified, experienced employees guarantee quality, efficiency and speed.

In addition to the usual machining methods, we are also equipped for hard milling, turning (with driven tools) and wire erosion. This enables us to manufacture complex injection moulding tools with offset separations, thread unscrewing cores, inclined slides, electric and hydraulic core pulls, etc.

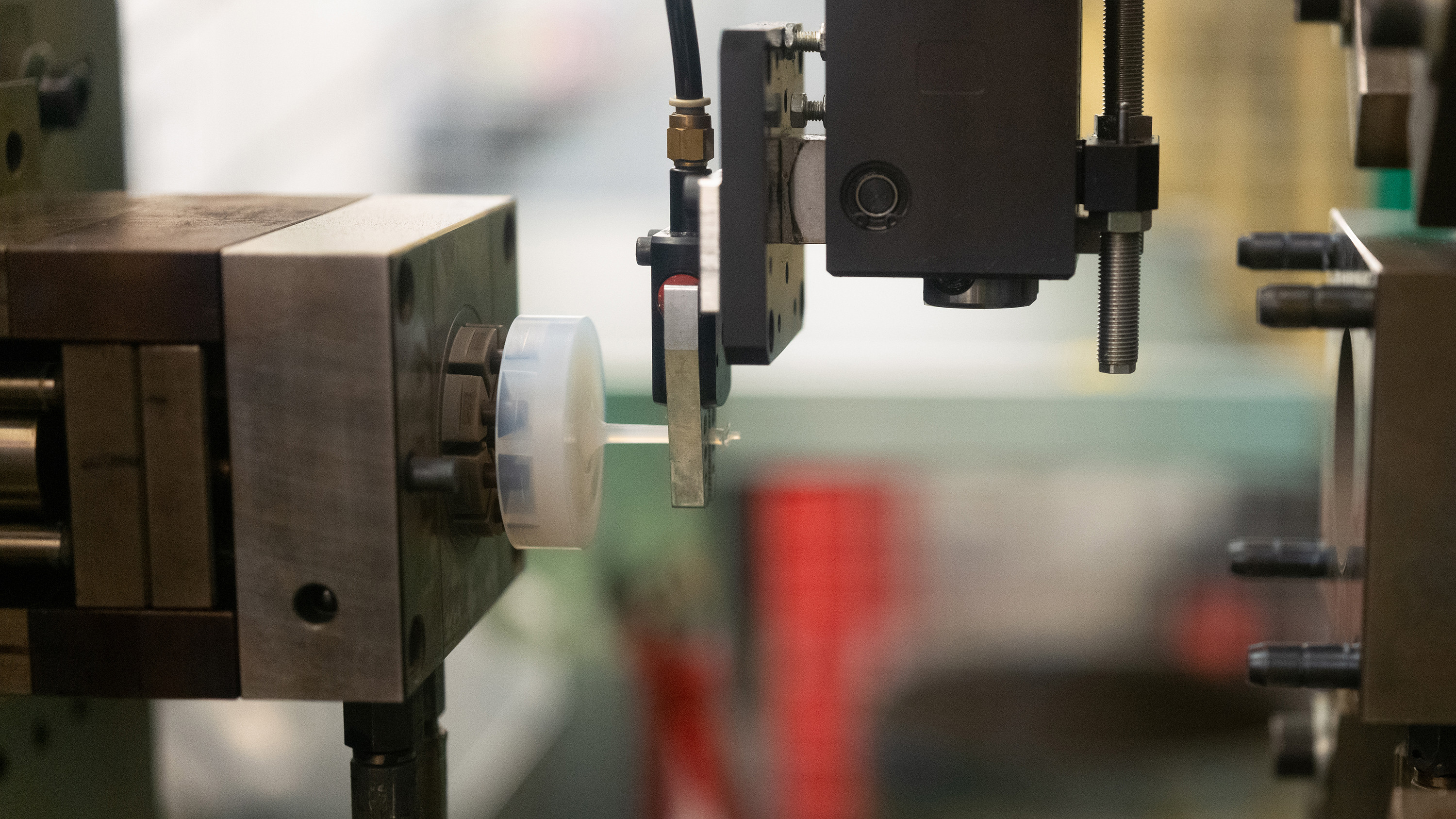

Injection moulding

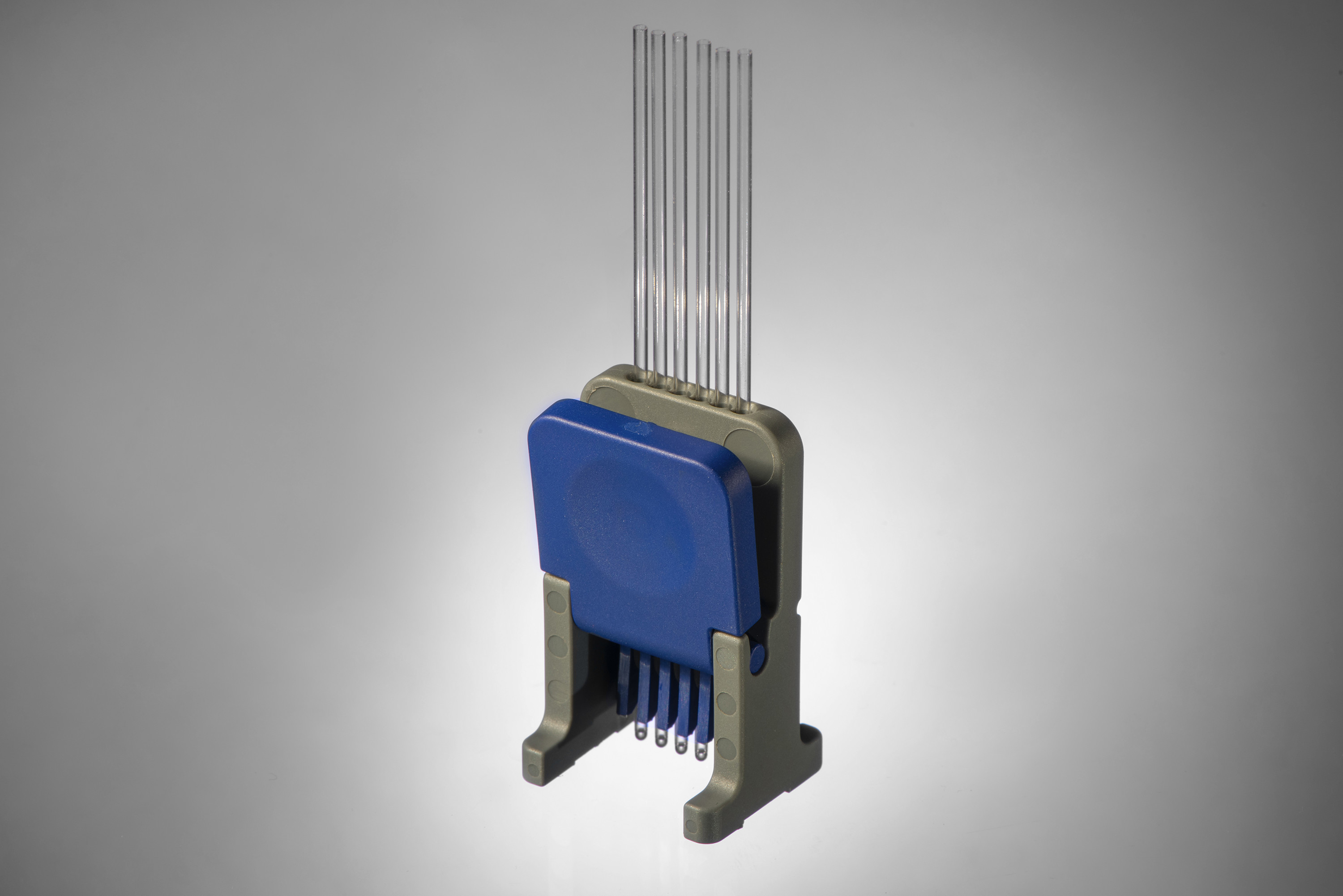

The production of complex technical parts from high-tech materials is our speciality, regardless of whether you have an annual requirement of 200 units or 10 million units.

We process all unfilled and reinforced thermoplastics except PVC and specialise in PEEK, LCP, PPS, PSU, PPA (PA HT) and fluoropolymers (e.g. Teflon PFA, PTFE, PVDF). Depending on your requirements, we can produce customised compounds or colours for you and will be happy to advise you on material selection.

We also have extensive experience in overmoulding inserts such as steel, glass, brass and plastic. We are also happy to carry out post-processing such as printing, painting, ultrasonic welding, mechanical reworking and assembly of your complete assemblies.

Machinery

Our modern machinery is constantly being updated and includes injection moulding machines with clamping forces of 180 to 1100 kN. We produce thin-walled parts with position-controlled injection units for high-precision, fast injection, if necessary with pressure accumulators. Depending on the technical requirements, we use fully electric or hydraulic machines with horizontal or vertical injection or clamping units, which can positively influence the fibre orientation, for example. Parts or sprues are automatically removed and deposited using removal robots.