Quality

Quality inspection

Introduction

When it comes to quality, we offer our customers the highest standards. If you have special requirements or needs, our specialists will be happy to advise you in order to work with you to ensure the optimum process for the quality testing of your products.

Our philosophy

To ensure the highest possible quality, KUNDERT inspects every component using at least the four-eyes principle.

- Initial sample test report

- Series inspection

- Final inspection

Systematic defect management

- Recognising faults before they occur wherever possible

- Recording of all defects

- Regular evaluation of the errors that occur

- Initiation and review of improvements and their effectiveness

Measurement options

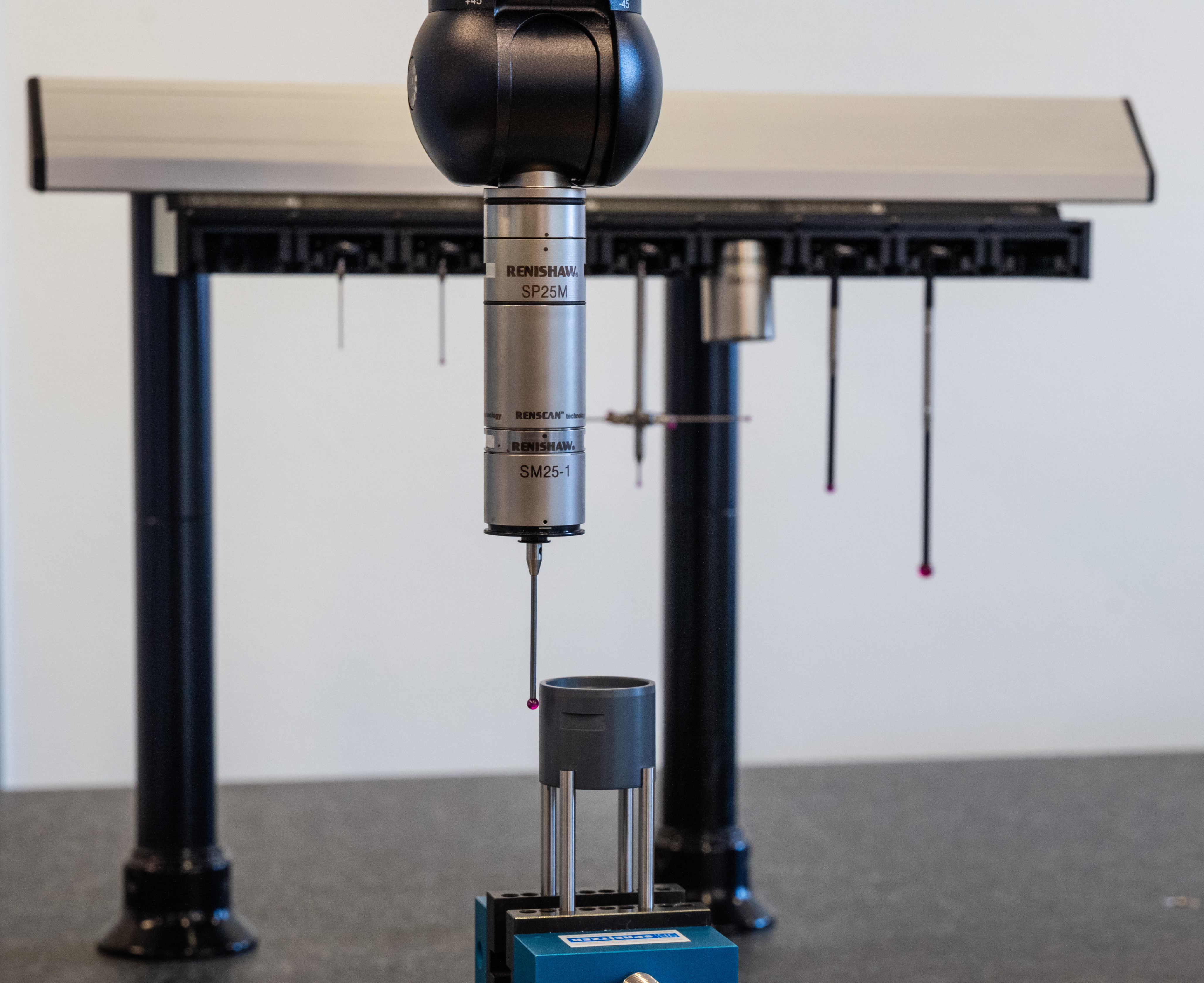

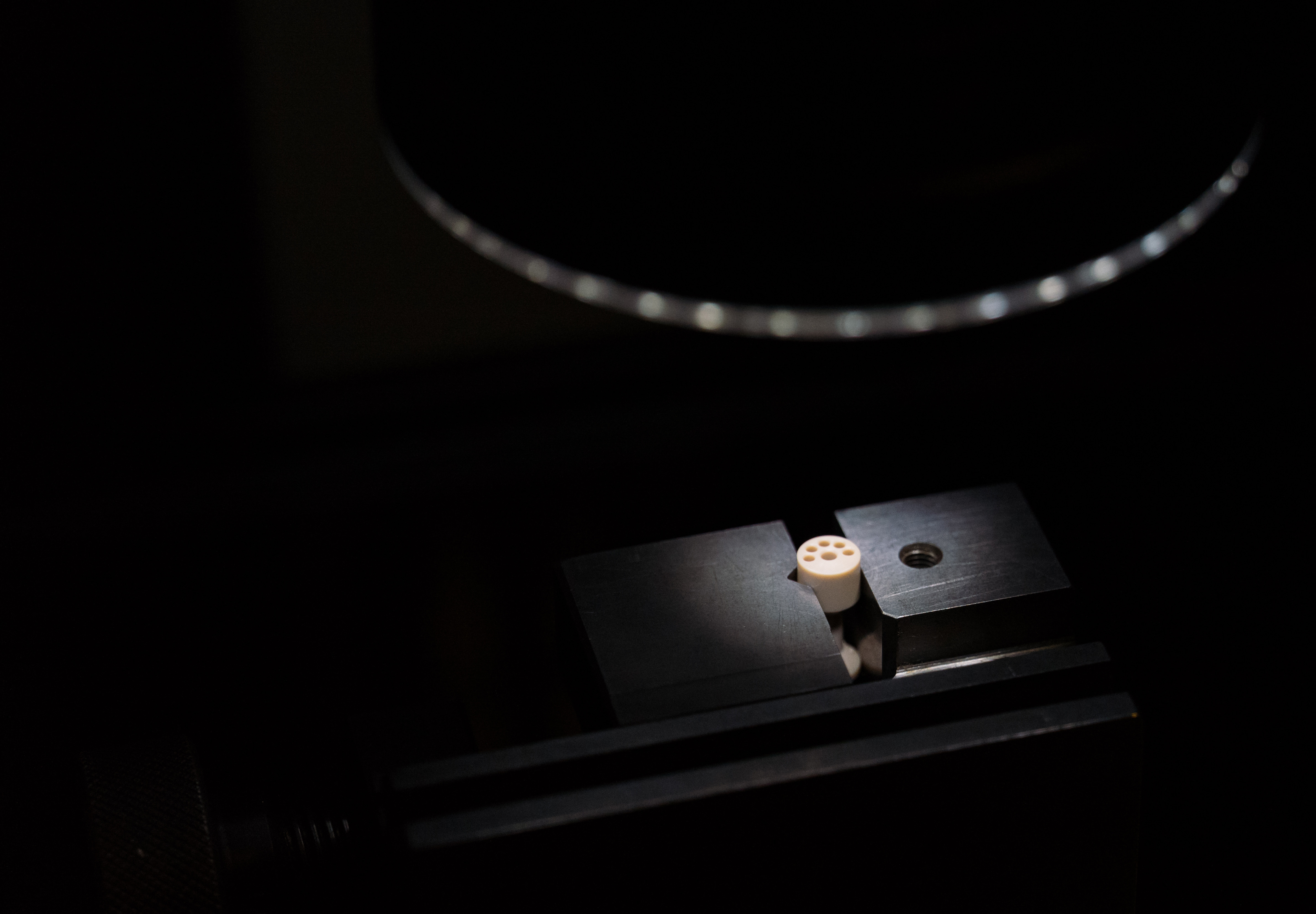

- 3D coordinate measuring machine

- Optical measuring devices

- Gauge testing

- Roughness measurement

- Shore hardness testing

Documentation

- Initial sample test report

- Test report

- SPC evaluation

- Testing according to AQL

- Customised tests

Material test certificates

A detailed overview of possible material test certificates can be found here.

Calibration

Periodic testing and calibration of all measuring equipment

Certificates

Quality management system according to ISO 9001:2015